|

|

Energy & Engineering

|

The Ruhr Area produces one-third of the energy used in Germany – billions of kilowatts per year. Energy research is conducted at the Energieforschung Ruhr Consortium based at TU Dortmund University, the NanoEnergieTechnikZentrum (NETZ) and the Fuel Cell Research Center (ZBT) at the University of Duisburg-Essen. Research focuses on: • Reducing carbon dioxide output in energy production. The Ruhr-Allianz ET & IT provides innovative inter- and transdisciplinary research opportunities and degree programs. Faculties of Mechanical Engineering at the Ruhr-Universität Bochum and TU Dortmund University have founded the virtual joint faculty Engineering Unit Ruhr, which focuses on energy and process engineering. The Club of Excellence, a joint effort of the Faculty of Business, Economics, and Social Sciences in Dortmund, and the Engineering Unit Ruhr, promotes industrial internships in engineering, supports talented students, and facilitates closer connections between TU Dortmund University, its students, and regional industry. |

|

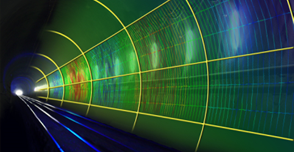

The DRD Subsurface Modeling and Engineering Department (SME) at the Ruhr-Universität Bochum focuses on the study of underground structures, the transparent underground, and engineering the underground. Research centers around the developments of models for the design, construction, maintenance and long-term behavior of underground structures, the development of numerical and experimental methods to better characterize the underground and the development of models for performance–oriented modification of the underground (fracturing, short- and long-term stability, permeability). The research will aid in meeting the challenges of a modern society: • eco-friendly development of energy sources and energy storage The SME cooperates with world-wide partners. The US collaborators include the California Institute of Technology, the Georgia Institute of Technology, the Massachusetts Institute of Technology, Stanford University, and the University of Southern California. |

|

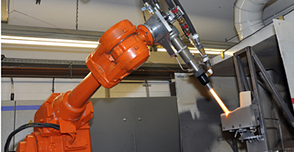

In the interdisciplinary Collaborative Research Center 3D Surface Engineering at TU Dortmund University, 21 scientists from the faculties of engineering, computer science, mathematics and statistics work together to develop novel methodologies for the production of free-form surfaces of tool systems of sheet metal parts production. This is important because free-formed sheet metal parts in the automotive industry |